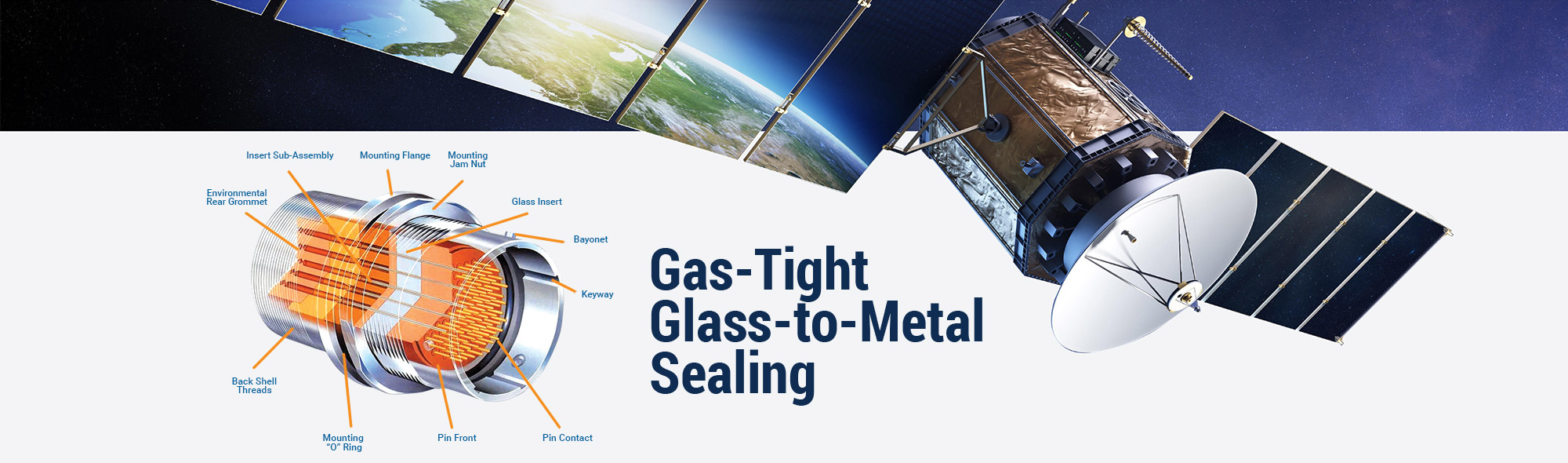

Look to DEUTSCH hermetic connectors from TE Connectivity (TE) for reliable, air- and gas-tight connections. For applications ranging from submarines and satellites to aircraft and offshore exploration and production, DEUTSCH hermetic connectors are an excellent choice for harsh application environments. We have four decades of experience in producing glass-to-metal seals for applications where temperature, pressure and environmental considerations render standard connectors unusable.

Hermetic connectors are used to separate an inert atmosphere or vacuum on one side from wide-ranging high-pressure, high-temperature, or corrosive conditions on the other. They are also used to maintain a pressure differential between the two sections. In short, DEUTSCH hermetic connectors are designed to help provide a continuously gas-tight seal while withstanding:

• Resists Temperature Extremes – Fiery Liftoffs to Cold Deep Space

• Provides a Solid Vibration-resistant Connection

• Withstands the Pressures of Undersea Applications

Standard sealing techniques – such as epoxy potting – are useful in many applications, but they do not provide the degree of near-perfect sealing that is offered by glass-to-metal hermetic seals. This is especially true of applications with high-pressure differentials. Glass is a durable, high-strength material that resists extreme changes in temperature or pressure.

Our glass-to-metal seals create a bond between shell, insulator, and contacts by fusing the glass insulator to the metal components. The bond can maintain a helium leak rate <1 x 10-7 He.atm.cm3/s at 14.7 psi. The hermetic bond provides enduring reliability, resists the cracking that would compromise the performance, and withstands a wide range of harsh conditions.

TE Connectivity DEUTSCH Connector Key Applications

| Aerospace | Engines | Missiles & Ordnance | Seismic | Offshore |

|---|---|---|---|---|

|

Actuation |

FADEC |

Optical Systems |

Land Seismic |

Ships |

|

Air Data Systems |

Pressure Sensors |

Inertial Guidance |

Cable Headers |

Subsea |

|

Bulkhead Feedthrough |

Temperature Sensors |

Electronic Boxes |

Hydrostreamers |

Deep Penetration Applications |

|

Fuel Utility Systems |

Torque Sensors |

|

|

|

|

Hydraulic Systems |

|

|

|

|